Firstly, one of the most critical aspects when selecting replacement parts is compatibility.

The replacement parts must be designed specifically for the Danfoss 90L pump to ensure proper fit and functionality. Using incompatible parts can lead to performance issues and potential damage to the pump.

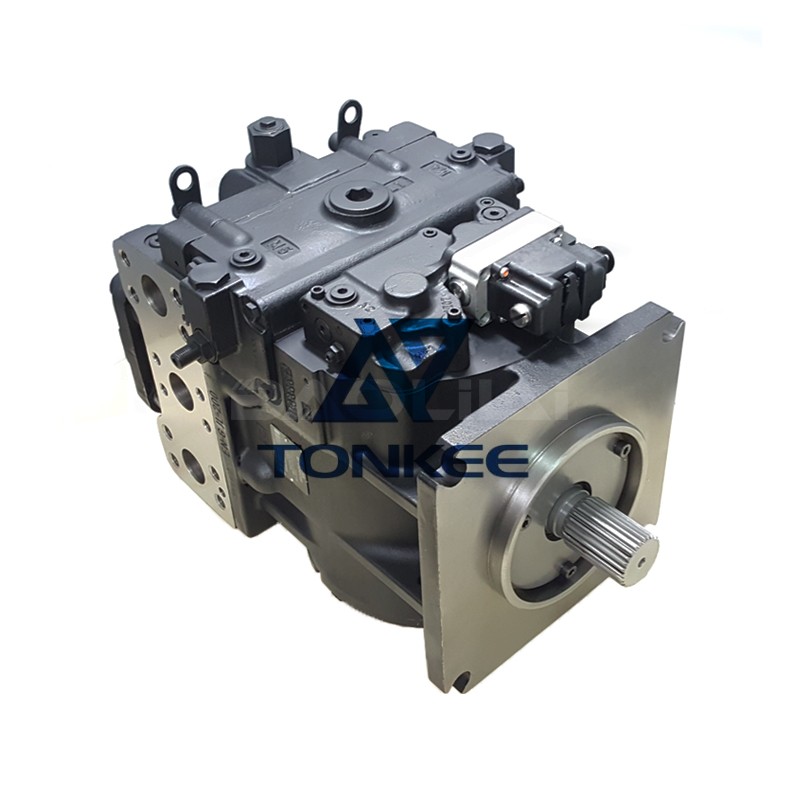

One of the key components of the hydraulic pump is the housing. The replacement housing should be made from high-quality materials that are resistant to wear, corrosion, and pressure. It is typically made from durable cast iron or steel to withstand the demanding conditions in which the pump operates.

Another crucial component is the rotor assembly. The rotor should be precision-machined to maintain the required tolerances and clearances. It is often made from high-strength alloy steel to ensure longevity and efficient fluid transfer. When selecting a replacement rotor assembly, it is essential to consider factors such as rotor size, geometry, and compatibility with the specific pump model.

The hydraulic pump also requires a set of high-quality seals to prevent leakage and ensure efficient operation. The replacement seals must be designed to withstand the pressures and temperatures involved in hydraulic systems. Common seal materials include nitrile rubber, polyurethane, and fluorocarbon, depending on the application requirements. It is crucial to select seals that match the original specifications to ensure proper sealing and prevent fluid loss.

Additionally, the replacement parts should meet or exceed the original manufacturer's specifications for performance and efficiency. This includes parameters such as flow rate, pressure rating, and overall volumetric efficiency. The replacement parts should be capable of delivering the required hydraulic power and maintain the system's performance.

Furthermore, it is important to consider the service life and maintenance requirements of the replacement parts.

Longevity is a key factor in reducing downtime and minimizing the overall cost of ownership. High-quality replacement parts that are built to last will provide extended service intervals and improved reliability.

Lastly, it is highly recommended to source replacement parts from authorized distributors or directly from the manufacturer. This ensures that the parts are genuine and meet the necessary quality standards. Using counterfeit or substandard parts can lead to severe consequences, including pump failure and safety hazards.