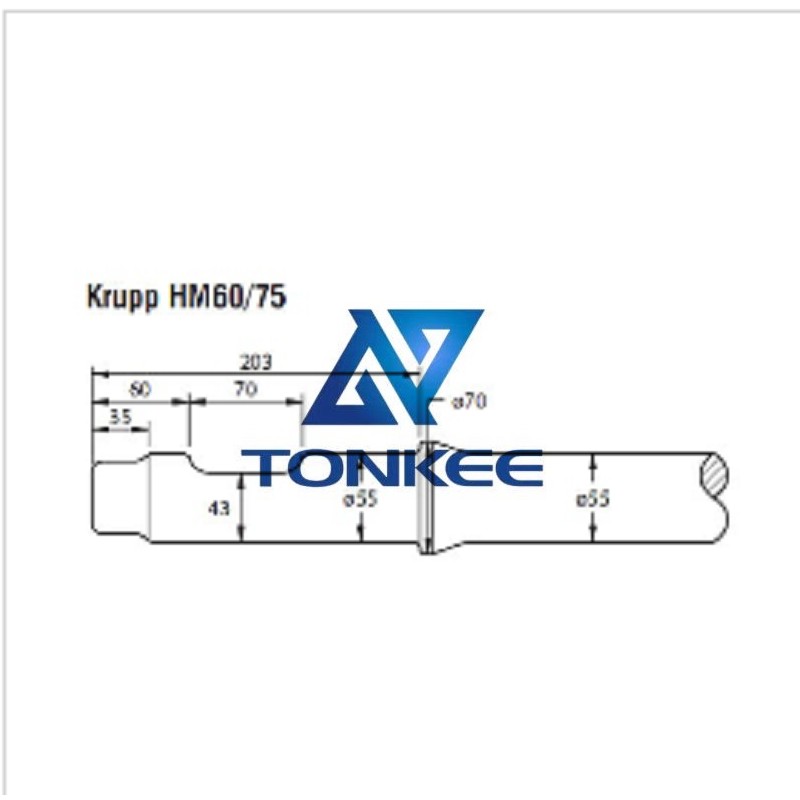

The moil point 55mm chisel is a key component of the Krupp HM6075 hydraulic breaker.

It is a hardened steel tool with a pointed tip, specifically designed to break apart rocks, concrete, and other hard surfaces. The chisel's 55mm width provides optimal force distribution, allowing for efficient and precise breaking of materials.

The hydraulic breaker itself operates by using hydraulic power to deliver high-impact blows to the surface being worked on. It is typically attached to an excavator or a similar hydraulic machinery, which provides the necessary power and stability for the breaker to perform effectively.

One of the notable features of the Krupp HM6075 is its exceptional power-to-weight ratio. Despite its compact size and lightweight design, this hydraulic breaker delivers a high level of impact energy, allowing for efficient and productive operation. The power of the breaker can be adjusted according to the specific requirements of the job, ensuring versatility and adaptability in different working conditions.

The Krupp HM6075 also incorporates advanced damping technology to minimize recoil and vibrations during operation. This feature not only enhances operator comfort but also reduces stress on the hydraulic system and extends the lifespan of the breaker.

Another important component of the Krupp HM6075 is the pipe driver, which allows for the installation and removal of pipes and posts.

This feature adds to the versatility of the breaker, making it suitable for a wide range of applications beyond rock breaking.

The durability of the Krupp HM6075 is ensured through high-quality materials and rigorous manufacturing standards. The moil point chisel is made from hardened steel, which provides excellent resistance to wear and abrasion. The breaker's housing and internal components are also built to withstand heavy use and harsh conditions, ensuring long-term reliability and performance.

In terms of maintenance, the Krupp HM6075 is designed for easy servicing. Routine maintenance tasks such as chisel replacement or lubrication can be performed quickly and efficiently, minimizing downtime and maximizing productivity on the job site.