The primary purpose of a hydraulic breaker flat chisel is to deliver powerful impact forces to break down rocks, concrete, and other hard materials.

Its flat shape provides a broad striking surface, enabling efficient force transmission and minimizing the risk of chisel damage. With its robust construction and high-quality materials, the MSB SAGA1000 chisel ensures durability and longevity, even under demanding operating conditions.

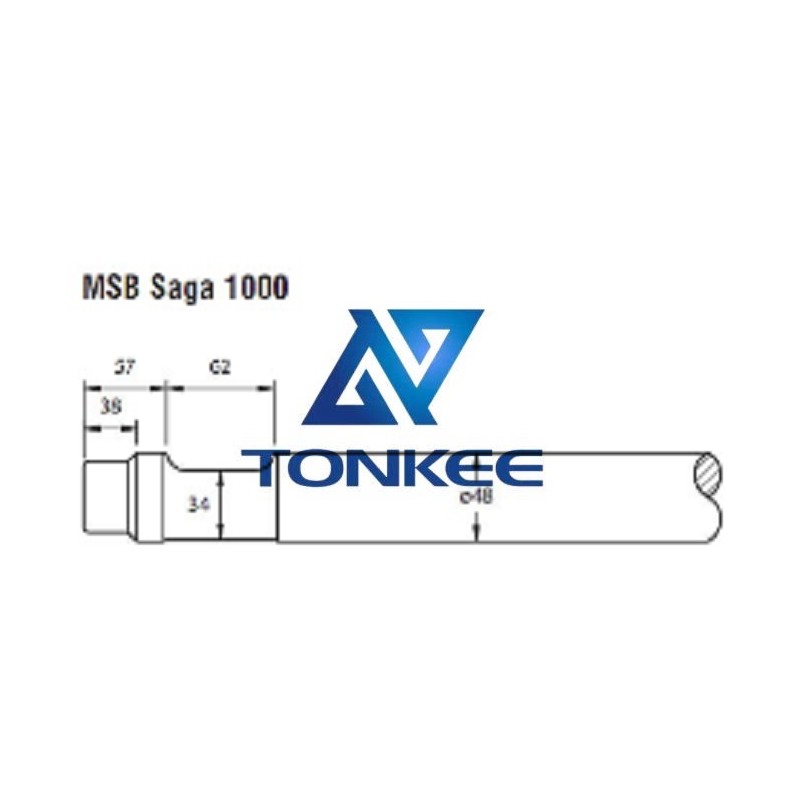

The chisel is specifically designed for use with the MSB SAGA1000 hydraulic breaker. It is crucial to select a chisel that matches the specifications of the breaker to achieve optimal performance and prevent compatibility issues. The 48mm width of this chisel allows it to fit perfectly within the breaker's housing, ensuring secure attachment and reliable operation.

Partsdic®, a trusted supplier of hydraulic breaker parts, adheres to strict quality control standards to deliver reliable and high-performance products. The MSB SAGA1000 Hydraulic breaker flat chisel undergoes rigorous testing to ensure its strength, durability, and resistance to wear and tear. By selecting this chisel, users can expect consistent performance and extended service life, reducing downtime and maintenance costs.

In addition to its robust construction, the MSB SAGA1000 chisel offers excellent striking power.

When attached to the hydraulic breaker, it harnesses the power of hydraulic pressure to generate rapid, forceful blows. These impacts effectively break apart tough materials, allowing for efficient excavation, demolition, or construction activities.

The 48mm width of the chisel makes it versatile for a range of applications. It can be used for breaking concrete slabs, rocks, pavement, and other solid structures. Whether it is for road construction, building demolition, or quarrying operations, the MSB SAGA1000 Hydraulic breaker flat chisel provides the necessary strength and durability to tackle demanding tasks.

Proper maintenance and care are crucial to ensure optimal performance and prolong the chisel's lifespan. Regular inspections and cleaning will help prevent debris buildup and maintain the chisel's effectiveness. It is also important to follow the manufacturer's guidelines for lubrication and replacement intervals to minimize wear and maximize the chisel's efficiency.