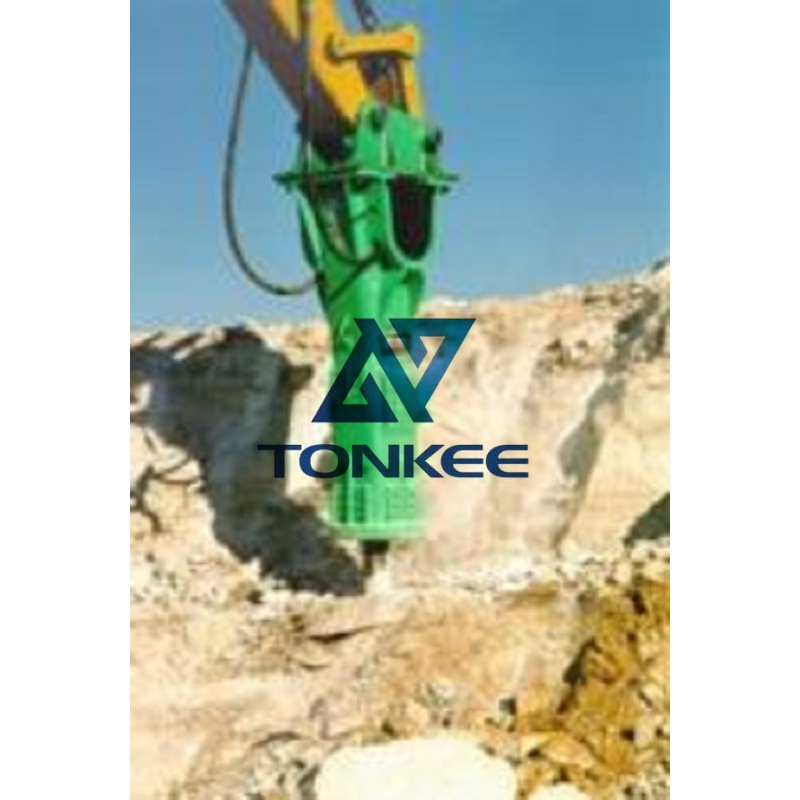

The V 65 hydraulic breaker hammer features a robust and compact design, making it easy to transport and install on different types of carriers, such as excavators and backhoes.

Its compatibility with a wide range of machines makes it a versatile and valuable addition to any construction or demolition project.

The hammer's main components include the housing, hydraulic cylinder, piston, tool holder, and working tool, which are engineered to work seamlessly together for optimal efficiency and power delivery. The housing is made from durable materials to protect internal components and maintain structural integrity during heavy-duty operations.

The hydraulic system plays a crucial role in the hammer's performance. It is powered by the carrier's hydraulic system, utilizing hydraulic oil under high pressure to generate the necessary force to strike the working tool against the material being broken. The V 65 hammer's hydraulics are engineered to minimize pressure drops and ensure maximum power transfer to the working tool, resulting in faster and more efficient breaking.

The piston, a key element of the hydraulic system, moves back and forth inside the cylinder, generating the striking force. It is designed to withstand substantial stress and pressure while maintaining a tight seal to prevent oil leaks.

The working tool, also known as the chisel or point, is the business end of the hydraulic hammer.

It comes in various shapes and sizes to suit different applications, whether it's breaking concrete, rock excavation, or secondary demolition tasks. The V 65 hammer's working tool is made from high-grade steel, ensuring its durability and resistance to wear and tear.

Montabert has integrated advanced damping and anti-vibration technology into the V 65 hammer, reducing vibrations transmitted to the carrier machine and operator. This not only improves operator comfort but also enhances the hammer's overall efficiency and prolongs the life of both the hammer and carrier components.

The V 65 hydraulic breaker hammer boasts impressive breaking power and energy efficiency, thanks to its optimized hydraulic design and precision engineering. It can deliver consistent blows with high impact energy, allowing for rapid material fragmentation and increased productivity on the job site.