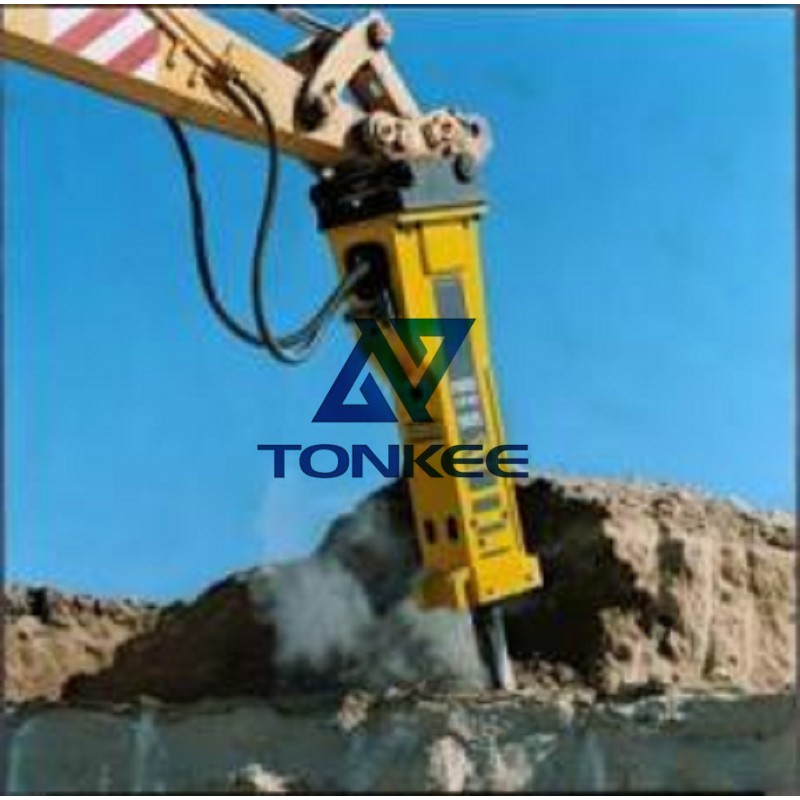

The MB 1700 features a robust design with high-quality materials, ensuring it can withstand the toughest operating conditions.

The breaker is constructed with a reinforced housing that protects critical components and minimizes the risk of damage during operation. Its compact and ergonomic design also enhances maneuverability and reduces operator fatigue, making it easier to handle and transport.

At the heart of the MB 1700 lies its advanced hydraulic system, which is responsible for generating the immense force required to break through various materials. The hydraulic system is designed for high efficiency, allowing the breaker to deliver maximum impact energy to the chisel at a rapid rate, resulting in improved productivity and reduced cycle times. Additionally, the hydraulic system is equipped with built-in safeguards to prevent overheating and ensure smooth operation, even during continuous heavy-duty use.

The MB 1700 incorporates an AutoControl feature, which optimizes performance by adjusting the impact energy and striking frequency based on the hardness of the material being broken. This intelligent automation not only increases efficiency but also minimizes wear on both the breaker and the carrier machine.

Partsdic®, a reliable distributor of construction equipment parts and accessories, offers a comprehensive range of spare parts specifically tailored for the Atlas Copco MB 1700 hydraulic breaker hammer.

These genuine parts are designed to meet the exact specifications of the original equipment, ensuring seamless compatibility and optimal performance. Customers can rely on Partsdic® to provide top-notch components, including chisels, pistons, diaphragms, seals, and other vital parts, helping to extend the service life and maintain the efficiency of their MB 1700 breaker.

Regular maintenance is crucial to maximize the lifespan and performance of the MB 1700 hydraulic breaker hammer. Partsdic® offers a wealth of resources, including maintenance manuals, technical support, and service kits, to help customers properly care for their equipment. Following the manufacturer's recommended maintenance schedule and using genuine replacement parts from Partsdic® will help prevent unexpected breakdowns, reduce downtime, and ultimately save on operational costs.