The A10VSO 31 series pump is manufactured by Rexroth, a renowned company known for its high-quality hydraulic products. As an Original Equipment Manufacturer (OEM), Rexroth ensures that the pump meets stringent standards and undergoes rigorous testing to guarantee its performance and reliability.

The OEM version of the A10VSO 31 pump comes with specific specifications and features that are designed to meet the requirements of various industries.

One of the key features of the A10VSO 31 pump is its variable displacement design. This means that the pump can adjust its output flow according to the system's demand, providing precise control and improved efficiency. It also offers a wide range of displacement options, allowing users to select the appropriate size for their specific application.

The pump is designed for high-pressure applications, with a maximum operating pressure of up to 350 bar (5075 psi). This makes it suitable for demanding hydraulic systems that require reliable and powerful performance. Additionally, the A10VSO 31 pump has excellent volumetric efficiency, ensuring minimal energy loss and maximizing the overall system efficiency.

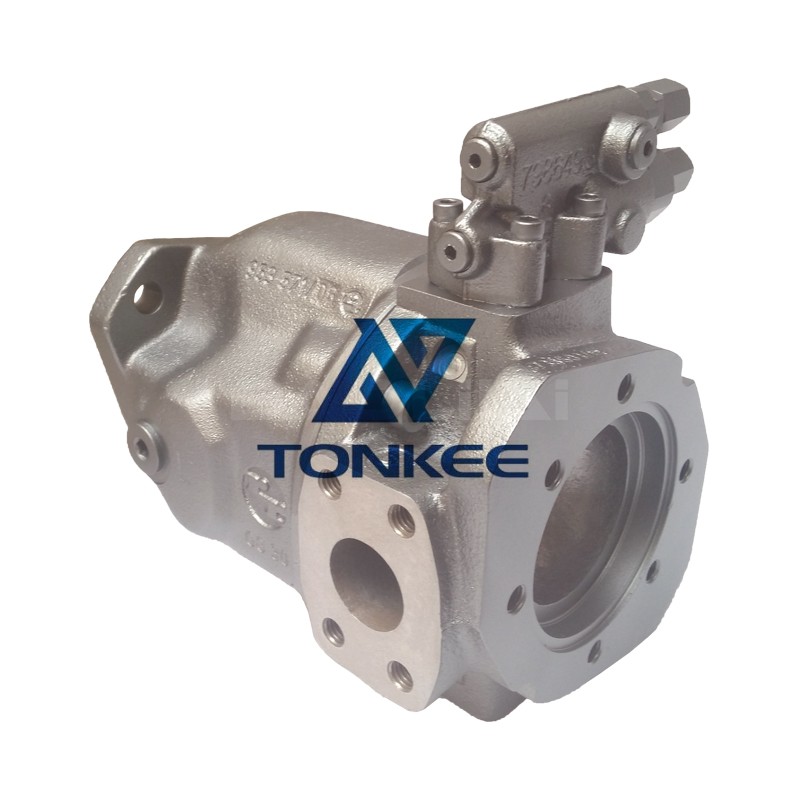

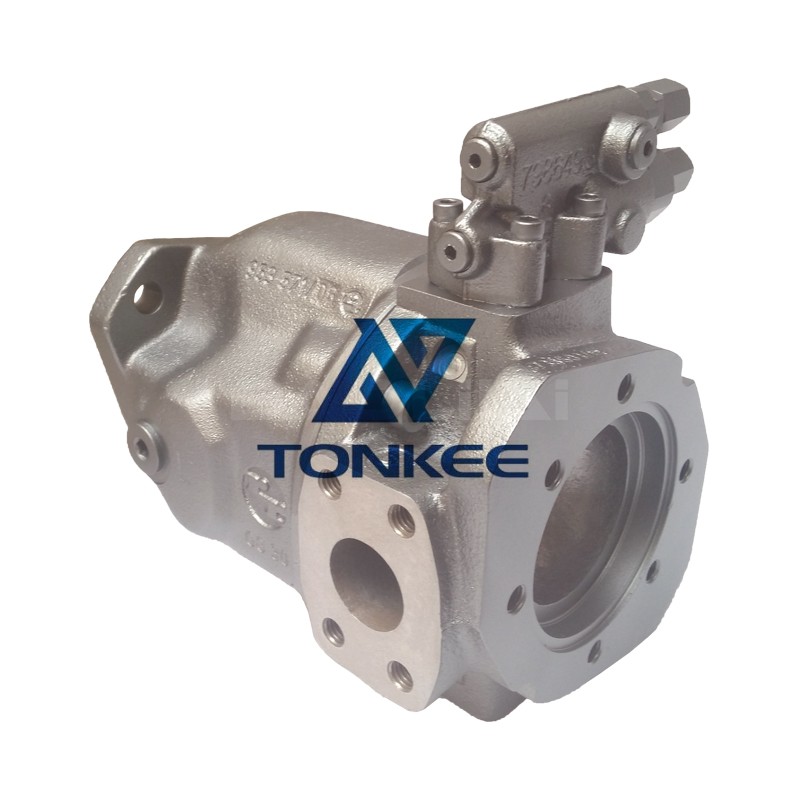

Another important feature of the A10VSO 31 pump is its robust construction.

It is built with high-quality materials and precise machining, ensuring durability and longevity even in harsh operating conditions. The pump's components are designed to withstand high pressures and provide reliable operation over an extended period.

In terms of aftermarket specifications, there are various options available for the A10VSO 31 series hydraulic pump. Aftermarket suppliers offer compatible pumps and spare parts that meet or exceed the OEM specifications. These aftermarket products are designed to provide reliable performance at a competitive price, offering cost-effective solutions for hydraulic system maintenance and repairs.

When selecting aftermarket products for the A10VSO 31 pump, it is crucial to ensure that they meet the necessary quality standards. Reputable aftermarket suppliers conduct thorough testing to validate the performance and compatibility of their products. By choosing reliable aftermarket options, users can maintain the performance and reliability of their hydraulic systems while reducing costs.